Latest Trends in PCB Manufacturing: Miniaturization, High-Density PCBs, and Advanced Materials

- Tina Thompson

- Jun 5, 2025

- 2 min read

Updated: Jul 12, 2025

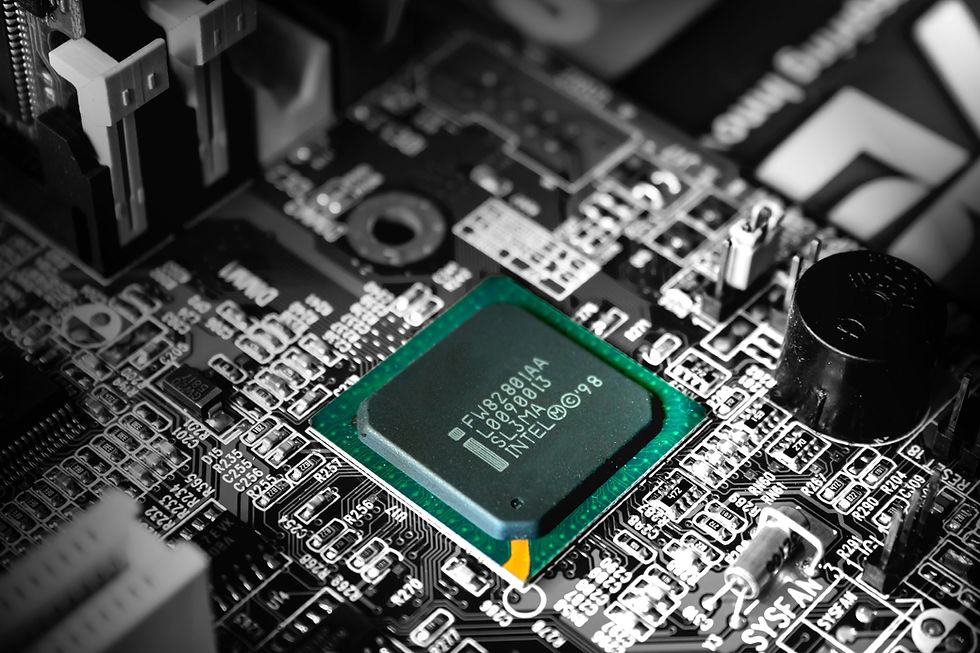

The world of PCB manufacturing is evolving rapidly, driven by the demand for smaller, more powerful electronic devices. As industries like telecommunications, automotive, aerospace, and consumer electronics push for innovation, PCB manufacturers are adopting new technologies to keep up. Here are some of the latest trends shaping the industry.

1. Miniaturization & High-Density PCBs

Electronics are shrinking, but their capabilities are expanding. This has led to the rise of high-density interconnect (HDI) PCBs, which allow for more components in a smaller space. Manufacturers are using microvias, finer trace widths, and multi-layer designs to achieve higher component density, improving signal integrity and electrical performance—especially for 5G and IoT applications.

2. Advanced Materials: Rogers & Teflon-Based Laminates

Traditional PCBs relied on FR-4, a glass-reinforced epoxy laminate. However, as performance demands increase, manufacturers are shifting to advanced materials like Rogers and Teflon-based laminates. These materials offer superior thermal management, mechanical strength, and electrical performance, making them ideal for high-frequency circuits, power electronics, and applications in aerospace and telecommunications2.

3. Sustainability & Green Manufacturing

Environmental concerns are reshaping PCB production. Manufacturers are adopting lead-free soldering, copper recycling, and biodegradable PCB substrates to reduce waste and minimize their ecological footprint. Additionally, energy-efficient production methods are becoming standard, driven by consumer demand and regulatory pressure.

4. AI & Automation in PCB Manufacturing

Artificial intelligence (AI) and automation are revolutionizing PCB production. AI-driven design optimization, automated assembly, and real-time quality control are improving efficiency and reducing costs. Robotics are also playing a key role in precision manufacturing, ensuring higher reliability and faster turnaround times.

5. The Future of PCB Manufacturing

Looking ahead, flexible and stretchable PCBs, embedded components, and 3D-printed circuit boards are expected to gain traction. As technology advances, PCB manufacturers will continue to innovate, ensuring that electronic devices become smaller, faster, and more efficient.

PCB manufacturing is at the forefront of technological evolution, and staying informed about these trends is crucial for businesses looking to remain competitive. Whether you're designing high-speed communication systems, automotive electronics, or medical devices, these advancements will shape the future of the industry.

Comments