The Complete Guide to PCB Prototyping for Startups

- Tina Thompson

- Jun 28, 2025

- 2 min read

Updated: Jul 12, 2025

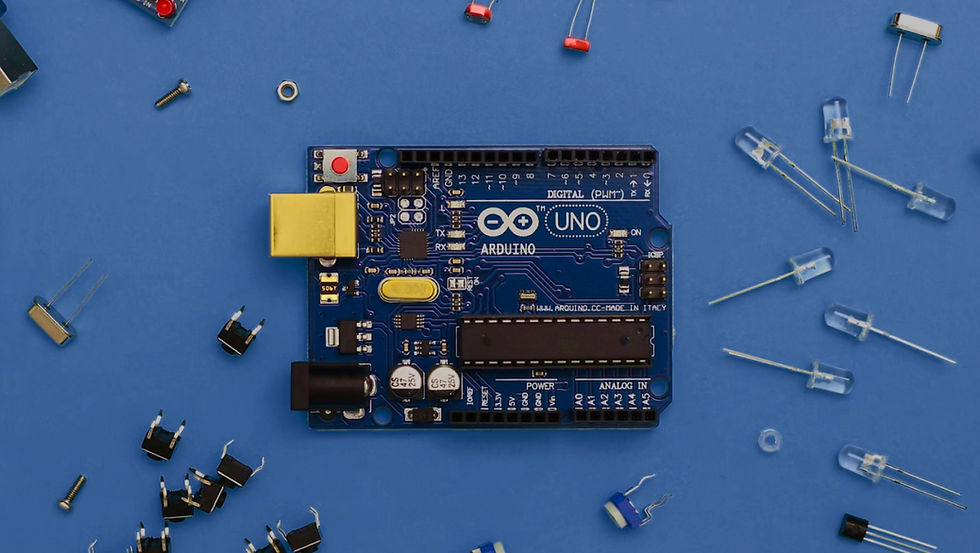

For company startups, speed, precision, and flexibility are mission-critical. Whether you’re building an entirely new product, refining a proof-of-concept, or exploring your first production-ready design, printed circuit board (PCB) prototyping is a key milestone on the road from idea to reality. This guide walks you through the five essential steps to successful PCB prototyping—with startup-friendly strategies woven in.

Step 1: Design with the End in Mind

Your PCB design should align with the bigger picture.

Define your mechanical constraints, form factor, and power requirements early

Use professional EDA tools like KiCad, Altium, or Eagle

Plan for scalability, component availability, and DFM (Design for Manufacturability)

Step 2: Generate a Reliable Gerber File Set

Think of Gerber files as the DNA of your prototype—they must be precise and complete:

Include copper layers, drill files, solder mask, and silkscreen

Verify for common issues: missing pads, unconnected nets, or format mismatches

Run DRC (Design Rule Checks) before submission

Step 3: Select Materials and Stack-Up

Your PCB’s materials and layer configuration affect everything from EMI shielding to mechanical rigidity:

Choose FR-4 for general-purpose builds

Use Rogers materials for RF or high-frequency boards

Optimize copper weight, layer count, and thickness for your use case

Step 4: Choose a Prototyping Partner Wisely

The right partner helps you move faster, smarter:

Look for manufacturers who support low-volume, quick-turn builds

Prioritize in-house DFM analysis, custom specs, and iteration support

Ask about engineering consultation and responsiveness

Step 5: Test. Iterate. Repeat.

No successful startup ships their first prototype untouched—iteration is key:

Perform electrical testing, thermal analysis, and real-world stress tests

Refine your design based on performance data

Use multiple cycles to converge on production-ready quality

Why Startups Choose 330 Electronics

At 330 Electronics, we know your prototype matters. That’s why we offer:

Low MOQs, fast turnaround, and engineering collaboration

DFM guidance, component sourcing, and stack-up strategy

A seamless path from prototype to full product assembly

Fulfillment options that ship direct to your production line or end customer

Build Smart. Iterate Fast. Scale Confidently.

Your prototype isn’t just a technical milestone—it’s your startup’s future. With a trusted partner like 330 Electronics, you're not just building a board. You're building momen

Comments